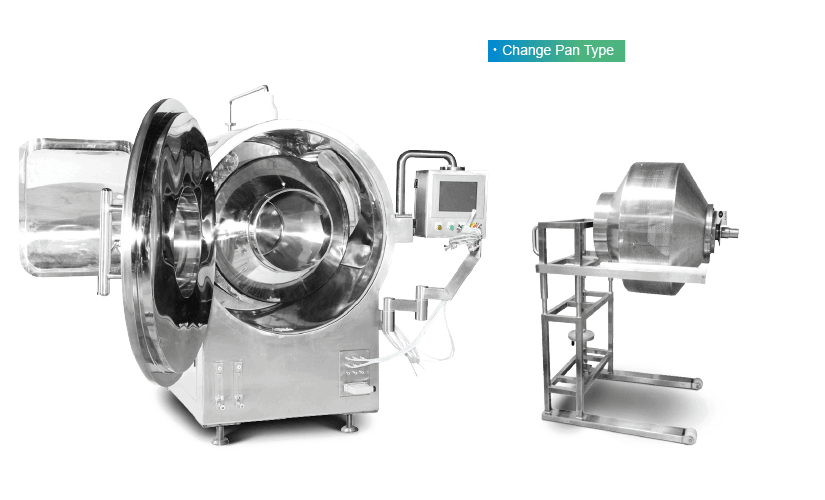

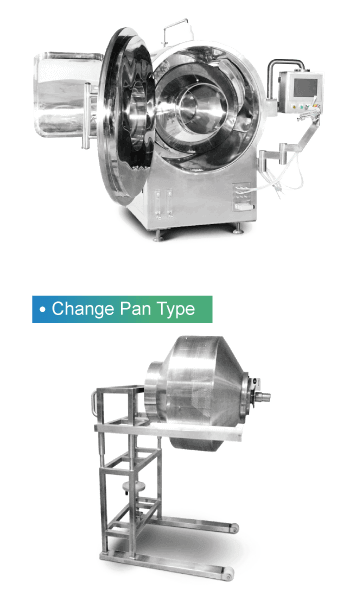

Super Coater

Super Coater

Function

- Film Coating:Spray one thin protection layer on the surface of tablet (used in aqueous or organic solvent).

- Enteric Coating:Spray one protection layer on the surface of tablet to against stomach acid.

- Sugar Coating:Multi-layers of sugar coated to protect the tablet.

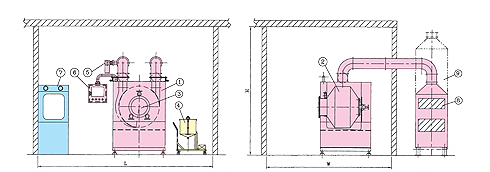

Theory

Hot airflow pass through a special designed film, heat the uniform rolling tablets inside, spray solution downward on the rolling tablet through pump and spray gun to get coating and drying purpose.Application

- Pharmaceutical:

- Western medicine:film coating, enteric coating, sugar coating, control released coating.

- Chinese medicine:film coating.

- Food:

- Film coating:agriculture products, crystal sugar health food.

- Sugar coating:chewing gun, yeast candy, health food.

- Seed:Protection layer coating or add nutrition.

Feature

- Film and sugar coating are in one machine.

- Punched hole pan design for efficient drying.

- Short operation time:

- Film coating:1 ~ 3 hr/batch.

- Enteric coating:3 ~ 4 hr/batch.

- Sugar coating:6 ~ 16 hr/batch.

- Explosion proof system is available for organic solvent process.

- Auto discharge system for easy discharge.

- Auto control design for sugar coating, even no experienced operator can easy operate also. Well mixed sugar syrup, automatic fixed amount and fixed time, easy operation.

- Uniform coloring, weight and smooth surface for sugar coating.

- Operation time about 6 ~ 16 hr/batch of sugar coating.

Specification

| Model | Diameter Tank (CM) | Capacity:Kgs/Batch | Size(W x L x H) (MM) |

|---|---|---|---|

| YS-FC-40F | 40 | 02-05 | 1200x1300x1600 |

| YS-FC-80F | 80 | 15-45 | 1400x2000x2000 |

| YS-FC-100F | 100 | 30-80 | 1500x2200x2000 |

| YS-FC-125F | 125 | 75-150 | 2200x2600x2400 |

| YS-FC-150F | 150 | 120-250 | 4000x4000x3000 |

| YS-FC-175F | 175 | 200-400 | 5000x5000x3500 |

| YS-FC-200F | 200 | 300-600 | 6000x6000x3700 |

Video

Super Coater

Super Coater

Fluid Bed Spray / Granulator / Coater

Fluid Bed Spray / Granulator / Coater

Centrifugal Granulator/Coater

Centrifugal Granulator/Coater