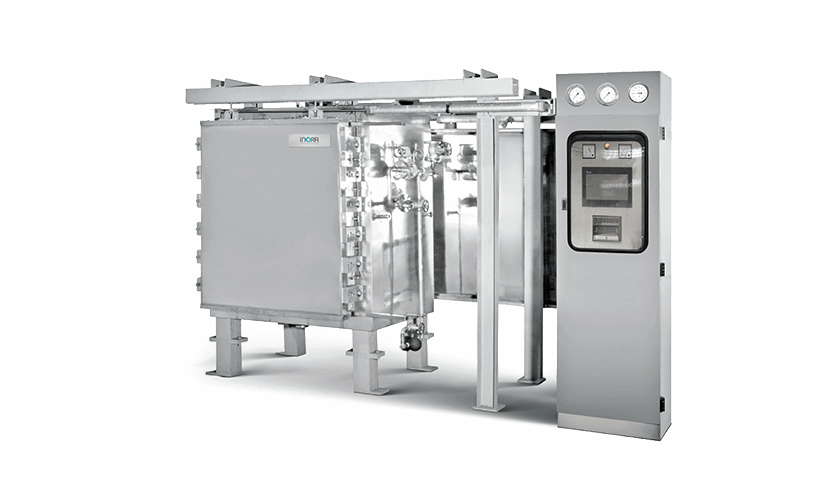

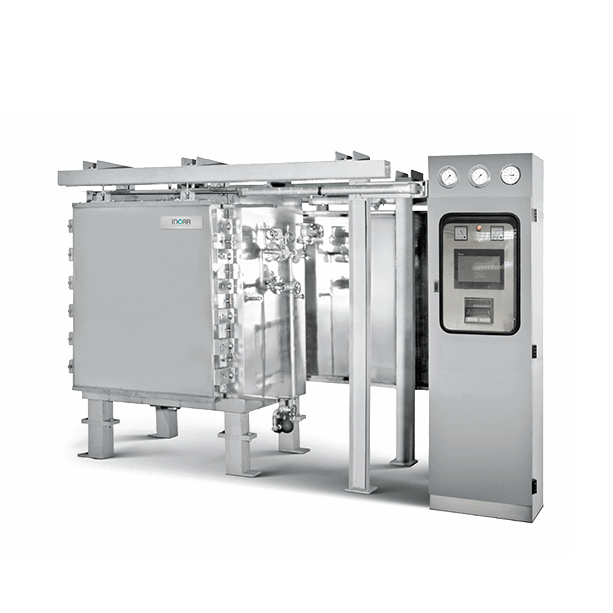

Steam Sterilizer

Steam Sterilizer

Function

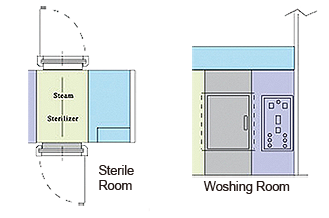

The sterilizer is commonly located between the washing room and sterilization room. The extermination of germs and micro-organisms can be achieved when the object for sterilizing is in the contained sterilization room with an essential high temperature and sufficient time; and therefore safer and more reliable products or instruments can be obtained.Application

Pharmaceutical、Food、Hospital、Research Laboratory.Feature

- Oil Hydraulic Door:the door clamping device uses an oil hydraulic cylinder to drive clamp for easier and contained operation.

- Steam Piping:steam piping fitting is made of sanitary pipe.The steam passes through one micro pre-filter 1μm

- Even Steam Distribution:by vacuum pump and entrance of steam into sterilization room during sterilization to achieve ±1 sterilization temperature.

- Fully Automatic Control:Adopt PLC control system, when the conditions have been set, the process will be controlled automatically.

- Temperature Recorder:records the temperature progress distribution completely and record pressure changes throughout whole sterilization process.

- Inspection Hole:validation testing holes are available for inspection.

- Computerized Operation:the computer can calculate the FO figure and shows that there is no more than one germ alive in one million of sterilized objects.

- Three Functions In One:integrated sterilization, cooling and leakage test to save time, energy, space and labor.

- Provide complete original record of sensors and calibration of all instruments.

Specification

| Model | Volume(L) |

Chamber Size (W x L x H) |

Dimensions (W x L x H) |

Steam Consump-tion (kg/hr) | Vacuum Pump(HP) | Weight(kg) |

|---|---|---|---|---|---|---|

| YS-SS-041 | 96 | 400x400x600 | 700x1300x900 | 60 | 1 | 1000 |

| YS-SS-061 | 360 | 600x600x1000 | 1000x1300x1300 | 100 | 2 | 1500 |

| YS-SS-081 | 800 | 800x1000x1000 | 1200x1700x1300 | 130 | 3 | 2000 |

| YS-SS-101 | 1440 | 1000x1200x1200 | 1400x1900x1500 | 200 | 3 | 3000 |

| YS-SS-102 | 2400 | 1000x1200x2000 | 14000x1900x2300 | 280 | 5 | 4000 |

| YS-SS-121 | 1872 | 1200x1300x1200 | 1600x2050x1500 | 240 | 3 | 3500 |

| YS-SS-122 | 3120 | 1200x1300x2000 | 1600x2050x2300 | 350 | 71/2 | 5000 |

| YS-SS-141 | 2680 | 1400x1600x1200 | 2000x2350x1500 | 310 | 5 | 4500 |

| YS-SS-142 | 4480 | 1400x1600x2000 | 2000x2350x2300 | 415 | 10 | 6000 |

| YS-SS-143 | 8060 | 1400x1600x3600 | 2000x2350x3900 | 630 | 15 | 9000 |

Steam Sterilizer

Steam Sterilizer